Maintaining uptime and reducing unplanned shutdowns is critical for any industrial operation—especially here in Singapore, where high labour and operational costs make downtime extra painful. In this post, we’ll walk you through what “predictive maintenance” really means, why it’s becoming a must-have for local plants, and how Bukom Engineering’s suite of services helps keep machines humming. We’ll also walk through a simple ROI example, share some industry statistics, and answer common questions.

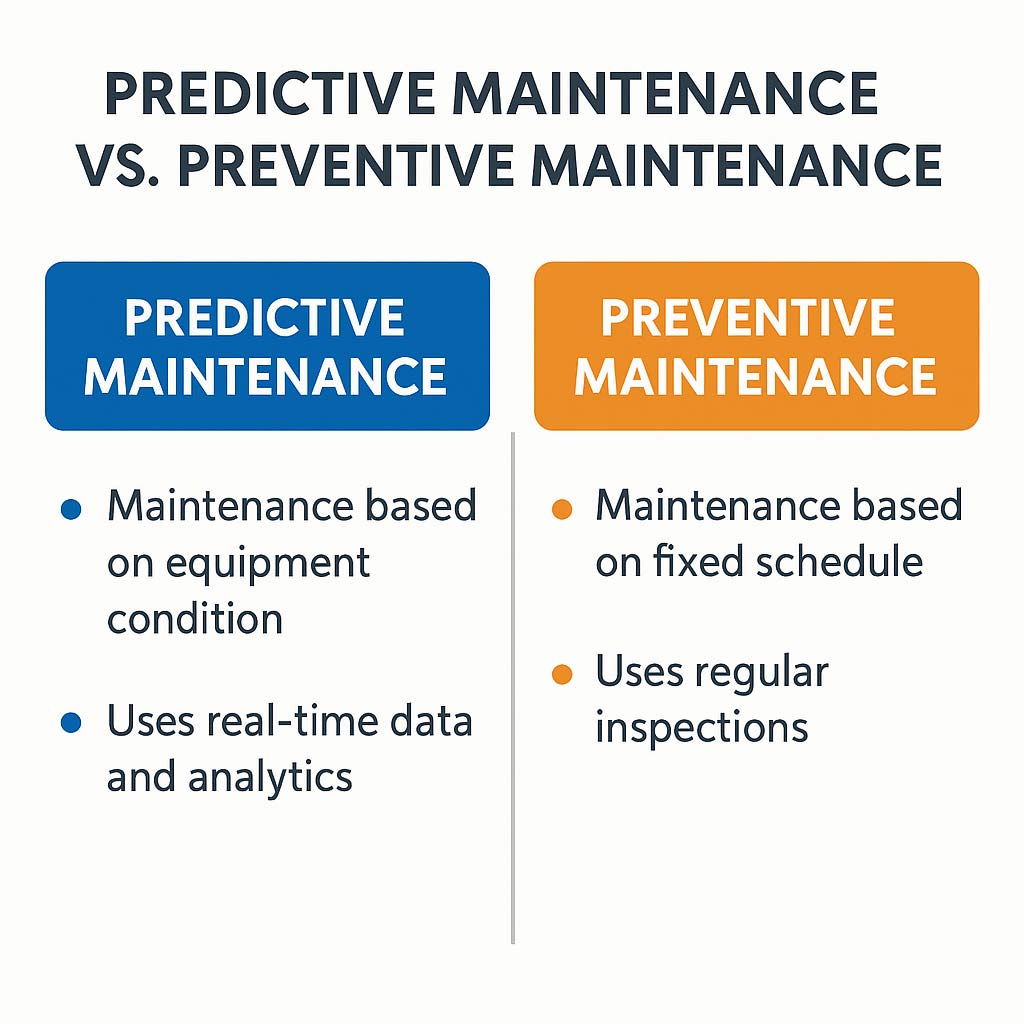

What Is Predictive vs. Preventive Maintenance

Definition of Predictive Maintenance

Predictive Maintenance Solutions uses real-time data—from sensors, vibration readings, thermal scans, and more—to anticipate equipment issues before they lead to a breakdown. Instead of swapping parts on a calendar schedule, engineers monitor machine health continuously and intervene only when the data signals an impending failure.

How It Differs from Preventive Maintenance

- Preventive maintenance follows a fixed schedule (e.g., change bearings every six months), regardless of the actual machine condition.

- Predictive maintenance relies on condition monitoring (e.g., vibration levels exceed an alarm threshold), so you replace or repair parts only when needed.

By avoiding unnecessary part changes and catching issues earlier, predictive strategies can shave maintenance costs by roughly 15–25% and reduce unplanned downtime by up to 30% (source: Wikipedia – Predictive maintenance).

Why Singapore Plants Need Predictive Methods Now

- High labour and production costs: Every hour of unscheduled downtime can cost tens of thousands of dollars.

- Complex equipment: Semiconductor fabs, pharmaceutical lines, and food-and-beverage plants operate at tight tolerances—unnoticed wear can cascade into major defects.

- Tight space and schedules: With land and shift costs high, plant managers can’t afford lengthy equipment changeovers. Predictive maintenance squeezes more life out of existing assets.

Top 5 Predictive Maintenance Solutions in Singapore

Vibration Analysis – Bukom’s In-House Service

How It Works: Bukom’s field engineers use portable vibration sensors on motors, pumps, and gearboxes to measure frequency signatures.

– Why It Matters Locally: In Singapore’s humid climate, bearings and seals degrade faster. Early vibration anomalies let you know when lubrication or a part swap is due—before a catastrophic bearing failure shuts down the line.

– Typical Findings:

– Imbalance in rotating shafts

– Misaligned couplings

– Looseness in housings

Thermal Imaging – Detecting Hidden Hot Spots

How It Works: Using handheld infrared cameras, Bukom engineers scan electrical panels, transformers, and rotating machinery to spot abnormal heat patterns.

– Local Benefit: High-humidity environments accelerate insulation breakdown. A small hotspot on a motor winding in Jurong’s data centers, for example, could signal that cooling has failed or a winding is shorting.

– Use Case: We recently detected an overheating pump motor in a pharmaceutical plant on Tuas Street—allowing maintenance to replace a worn bearing before it seized.

IoT Sensor Integrations – Real-Time Monitoring

How It Works: Bukom installs rugged, wireless sensors (temperature, vibration, humidity) directly on critical assets. These feed live data to a cloud dashboard.

– Why Singapore Plants Adopt It: Space constraints often mean you can’t stand by every machine. With IoT sensors pinging updates every few minutes, technicians get alerts on their tablets or phones.

– Popular Platforms: We integrate with local SCADA systems or popular global platforms—with plug-and-play nodes that transmit over LoRaWAN or NB-IoT for reliable coverage in large facilities.

AI-Driven Analytics Platforms – Regional Overview

How It Works: Raw sensor outputs (vibration spectra, temperature logs) get ingested by AI models trained to detect patterns that precede failures.

– Singapore Context: A handful of regional startups offer subscription-based analytics dashboards that benchmark your machine’s “normal” behaviour against thousands of similar assets in local plants.

– Bukom’s Role: We combine our in-house expertise with these platforms, helping clients tune alert thresholds to avoid false positives. That means fewer nuisance alarms and more actionable insights.

Cloud-Based Maintenance Dashboards – Benefits for Managers

- How It Works: A web portal aggregates all sensor inputs, vibration analyses, and inspection reports in one place—accessible 24/7 from any browser.

- Value for Singapore Executives: During off-hours or when travelling, plant managers can check KPIs like machine availability, next-service dates, and open work orders at a glance.

- Example Widget: A colour-coded uptime gauge shows percent uptime for each production line—green above 97%, yellow 90–97%, red below 90%.

Example: What You Can Expect from Predictive Maintenance

Below is a realistic scenario—based on Bukom Engineering’s typical Singapore engagements—to illustrate the kinds of outcomes you might see when implementing vibration and thermal scanning. These figures use industry averages and local context rather than a specific fictional client.

Hypothetical Facility: Mid-Sized Data Center on Jurong Island

- Facility Profile: A colocation data centre with 50 rack units, critical cooling-fan systems, and multiple chillers.

- Pain Points:

- Frequent cooling-fan motor failures causing brief server rack temperature spikes.

- Emergency maintenance calls that cost roughly S$2,500 per event (parts + after-hours labour).

- Unplanned downtime valued at approximately S$7,000 per hour (lost revenue, SLA penalties, energy inefficiency).

Phase 1: Initial Condition Audit

- Vibration Scans on Fan Motors

- Engineers place handheld vibration probes on each fan motor.

- Within one week, anomalies emerge: two fan motors show bearing vibration levels 25–30% above normal thresholds.

- Thermal Imaging on Electrical Panels

- Infrared camera sweep of motor control panels reveals two spots running 15–20 °C hotter than adjacent areas—typical sign of early winding insulation breakdown.

Expected Insight: You’ll identify 2–4 assets (e.g., fans, pumps) that need bearing lubrication or minor repairs within 30–60 days—rather than discovering a seizure only after failure.

Phase 2: Targeted Intervention

- Scheduling Repairs During Planned Maintenance Window

- Instead of emergency after-hours calls, the facility schedules bearing replacement for the two flagged fan motors over a standard daytime maintenance slot.

- Emergency repair budget drops by about 75% (from three unplanned calls per quarter down to one minor service).

- Immediate Thermal Remediation

- Engineers adjust cooling airflow in hot-spot areas and replace a failing capacitor in a panel, preventing an imminent short.

Expected Outcome (First 3 Months):

– Emergency maintenance calls drop from 3 events to 1 event.

– Estimated savings from avoided after-hours labour and express parts:

– Previous cost: 3 × S$2,500 = S$7,500

– New cost: 1 × S$2,500 = S$2,500

– Short-Term Savings: S$5,000 over three months.

Phase 3: Ongoing Monitoring & ROI Estimate

- IoT Sensor Setup on Top 10 Critical Motors

- Wireless vibration/humidity sensors transmit data every 15 minutes to a cloud dashboard.

- Alerts configured to trigger when vibration exceeds 20 mm/s or temperature rises above 60 °C.

- Quarterly Thermal Audits

- Infrared camera walk-through every three months to catch any new hot spots.

Projected Benefits (12 Months)

| Metric | Baseline | With Predictive Maintenance | Improvement |

|---|---|---|---|

| Unplanned downtime (hours/year) | 12 hours | 6 hours | –50 % |

| Cost per hour of downtime | S$7,000 | S$7,000 | — |

| Emergency repair calls per year | 12 events | 4 events | –67 % |

| Cost per emergency event | S$2,500 | S$2,500 | — |

| Annual cost of predictive maintenance programme | — | S$15,000 (sensors + audits) | — |

| Total Annual Savings Estimate | — | — | S$61,000 |

- Downtime Reduction Savings:

- Avoided downtime = (12 – 6) × S$7,000 = S$42,000

- Emergency Repair Savings:

- Avoided calls = (12 – 4) × S$2,500 = S$20,000

- Minus Annual Programme Cost:

- S$42,000 + S$20,000 – S$15,000 = S$47,000 net savings

These numbers assume a mid-sized facility typical of many Singapore data centres. Your actual results will vary based on your asset mix, failure rates, and repair cost structure, but this table offers a conservative estimate of what you could expect.

Key Takeaway:

By identifying issues early with vibration probes and thermal scans, you can cut unplanned downtime by around 50% and reduce emergency repair calls by up to 67%. Even after accounting for the predictive maintenance programme cost (approximately S$15,000 per year), the net savings for a mid-sized data centre can exceed S$40,000 annually.

For a custom estimate tailored to your plant’s equipment and operating profile, reach out to Bukom Engineering’s team. We’ll run a quick feasibility assessment and show you exactly which assets to monitor first and how soon you’ll see returns.